Whether you require Ballard to deliver low quantities of a fuel cell component prototype or mass produce fuel cell stacks, Ballard has the scale to reduce costs and speed your time to market. Leverage existing Ballard designs or manufacture to custom specifications using state-of-the-art prototyping and high volume equipment.

Whether you require Ballard to deliver low quantities of a fuel cell component prototype or mass produce fuel cell stacks, Ballard has the scale to reduce costs and speed your time to market. Leverage existing Ballard designs or manufacture to custom specifications using state-of-the-art prototyping and high volume equipment.

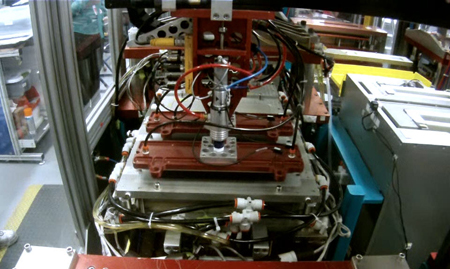

Ballard’s manufacturing solutions include:

- In-house catalyst coated films and catalyst coated membranes (roll to roll)

- Bipolar plate assembly

- MEA framing and liquid injection mold sealing

- Fuel cell stacks and system assembly and factory acceptance testing

- MEA, stack, and system assembly process design, transfer and training

- Process scale-up support